Understanding TMT Global Technology Ltd’s Net Cable Colour Code for the Saudi Arabia Market

Introduction to TMT Global Technology Ltd

TMT Global Technology Ltd is a distinguished player in the cable manufacturing sector, established with the vision of delivering high-quality products tailored specifically for the Saudi Arabian market. Founded in an era marked by technological advancement, TMT has consistently prioritized innovation and excellence in its manufacturing processes. The company’s headquarters are strategically located to facilitate efficient operations and ensure prompt distribution across the region.Net Cable Colour Code

With a keen focus on meeting the evolving demands of the telecommunications and electrical industries, TMT Global Technology Ltd specializes in the production of various types of cables, including but not limited to, low voltage, high voltage, and specialty cables. This diverse portfolio positions the company as a vital partner for businesses seeking reliable and durable cable solutions. The organization’s commitment to adhering to international quality standards ensures that all products are rigorously tested and certified, thus enhancing their reliability and performance.

cat6 cable brands list

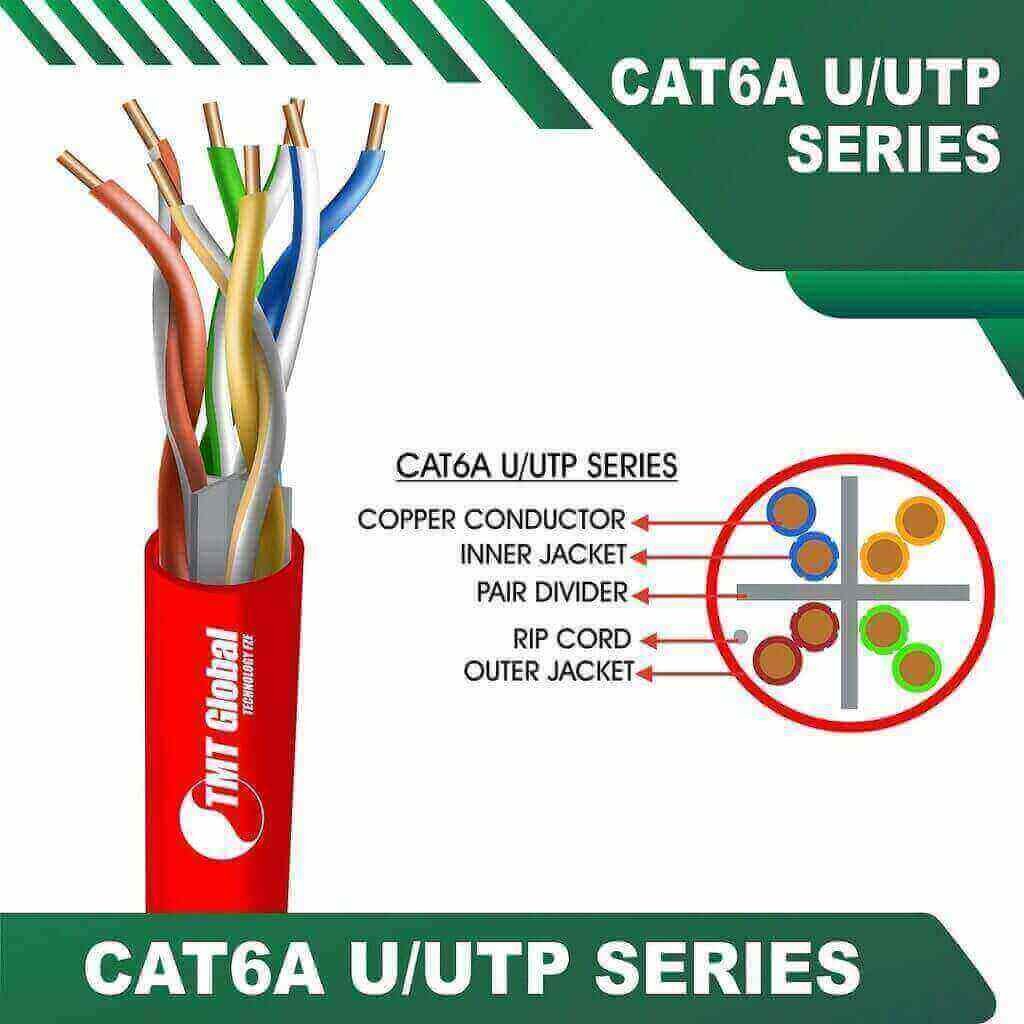

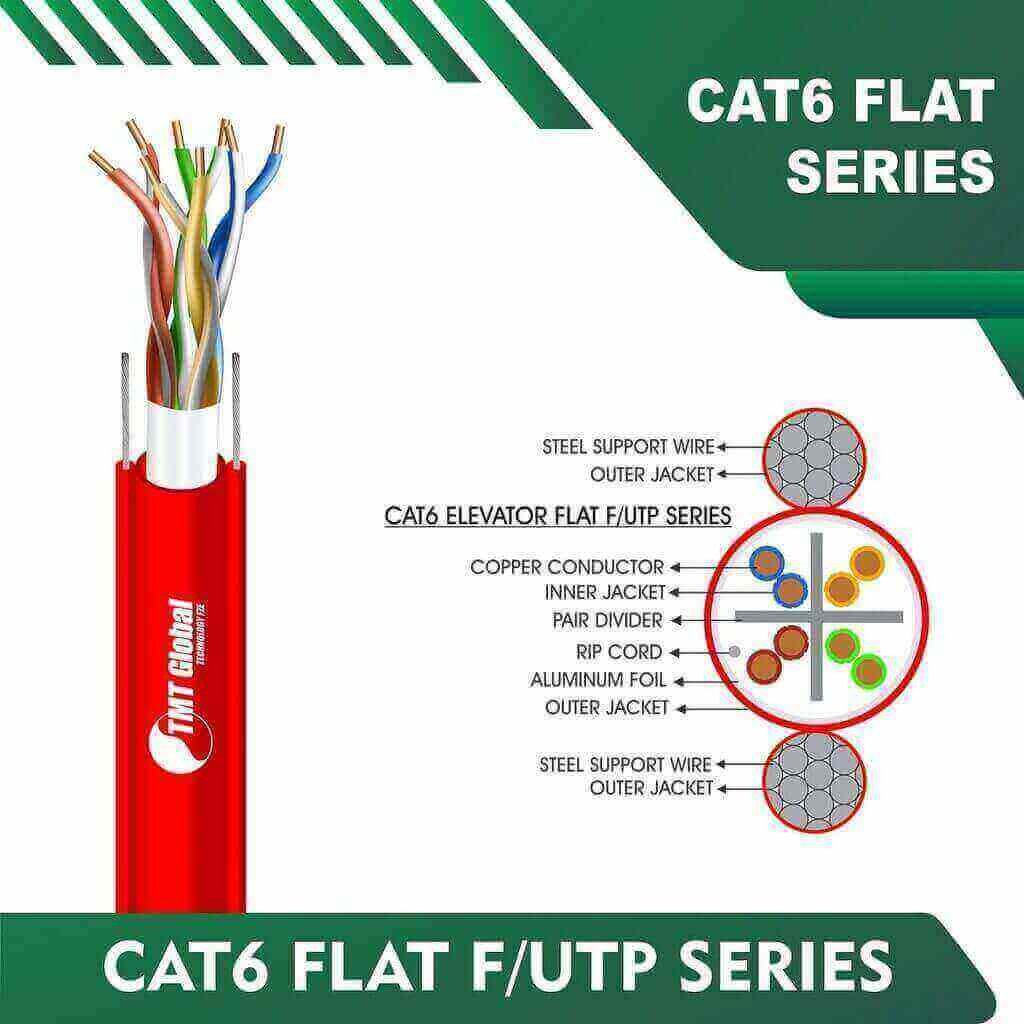

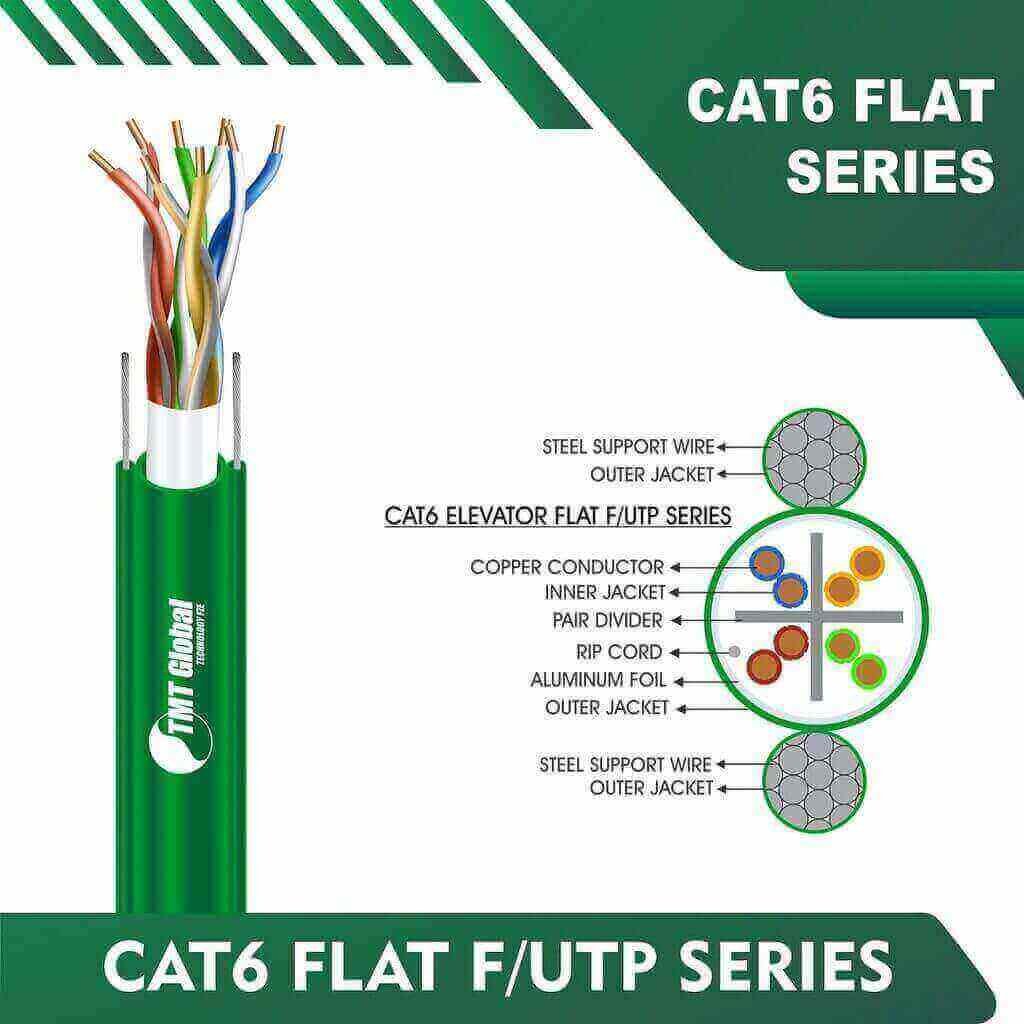

cat6 cable diagram

In addition to its strong manufacturing capabilities, TMT Global Technology Ltd embraces a forward-thinking approach driven by research and development. This initiative not only enhances the product offerings but also incorporates the latest technological trends. By tapping into the insights gathered from market analysis, the company aligns its production with the specific preferences and requirements of its clients in Saudi Arabia, further solidifying its reputation in the industry.

As TMT Global Technology Ltd continues to expand its reach and elevate its product quality, its role in the region’s infrastructure development becomes increasingly significant. The company’s focus on customer satisfaction and innovation reflects its dedication to fostering long-term relationships with clients and stakeholders, ultimately positioning TMT as a leader in the cable manufacturing sector within Saudi Arabia.

Importance of Colour Coding in Net Cables

Colour coding in net cables is an essential practice that facilitates various processes in the realm of networking. Primarily, a well-established colour coding system enables easy identification and differentiation of different cables during installation, maintenance, and troubleshooting. Each cable type can be designated a specific colour, making it easier for technicians to swiftly recognize the purpose of each cable, which is crucial in a bustling environment such as data centres or telecommunications networks. This practice can significantly reduce the time spent on cable management and enhance overall operational efficiency.

Furthermore, the accuracy of colour coding used in net cables is crucial for ensuring maximal performance and safety in network systems. Misidentification of cables can lead to incorrect connections, resulting in network failures or even equipment damage. By adhering to a standardized colour coding scheme, organizations can mitigate the risks associated with cabling errors, thus bolstering the reliability of their network infrastructures. Consistent colour coding also supports effective troubleshooting. When network issues arise, technicians can quickly trace and resolve problems by following the colour-coded cables, which aids in restoring normal operations without unnecessary delays.

Moreover, colour coding contributes to safety protocols within network installations. Properly colour-coded net cables help prevent accidental disruptions such as cable cross-connections, which can create hazardous situations, especially in networks that handle sensitive data. By implementing an intuitive colour coding scheme, organizations ensure that their staff can work more safely and efficiently, ultimately protecting both human resources and technological investments.

In conclusion, the importance of colour coding in net cables cannot be overstated. It plays a pivotal role in enhancing identification, improving network performance, ensuring safety, and easing maintenance tasks. For TMT Global Technology Ltd., adhering to these principles in the Saudi Arabia market will serve to streamline operations and safeguard their networking solutions.

Overview of Net Cable Specifications

TMT Global Technology Ltd specializes in the production of high-quality net cables tailored for the Saudi Arabia market. These cables are essential for providing reliable network connections, which are crucial in today’s technology-driven environment. The company offers a range of products, including Cat5e, Cat6, and Cat6a cables, each varying in performance capabilities and use cases.

Cat5e cables are designed to support data rates up to 1 Gbps, making them suitable for basic networking needs, such as internet browsing and standard office applications. On the other hand, Cat6 cables provide enhanced performance, facilitating data rates of 10 Gbps over shorter distances. This makes them an excellent choice for environments requiring higher speeds, such as data centers and corporate networks. Cat6a cables further extend these capabilities, providing speeds up to 10 Gbps over longer distances, and are ideal for bandwidth-intensive applications.

The materials used in the manufacturing of these cables often include high-grade copper conductors, which ensure minimal signal loss and superior transmission quality. The insulation materials and overall cable structure are engineered to reduce crosstalk and interference, supporting consistent performance even in demanding environments. Compliance with both international and Saudi Arabian standards, such as ANSI/TIA and ISO/IEC requirements, is critical. These compliance measures ensure that TMT Global’s cable products are reliable and up to the necessary specifications for safety and efficacy.

As technology evolves, the importance of understanding cable specifications, including their colour coding systems, becomes vital. These specifications provide insights not only into the performance of the cables but also offer guidance for proper installation and connectivity applications. With a solid grasp of these net cable specifications, customers can ensure optimal network performance tailored to their specific needs. As we delve deeper into the colour coding, we will explore how these technical attributes relate and enhance functionality.

TMT’s Unique Colour Code for Saudi Arabia

TMT Global Technology Ltd has established a distinctive colour code for its net cables designed specifically for the Saudi Arabian market. This thoughtful implementation allows for easier identification and categorization of different types of cables, enhancing both installation and maintenance processes. The colour coding system is not only practical but also aligns with local preferences and standards.

The system is composed of several key colours, each representing a specific function or type of cable. For instance, the primary colour typically used for power cables is black, while blue often indicates data transmission cables. Red is utilized for cables that handle communication signals, facilitating quick identification during installation or troubleshooting. This stratification helps reduce confusion, especially in environments where multiple cables coexist.

Additionally, TMT has integrated a series of stripes within their colour code to denote variations in specifications. For example, a solid yellow cable may indicate a standard model, while a solid yellow cable with a green stripe signifies a cable designed for heavy-duty applications. Such variations enable technicians to choose the right cable for their specific needs quickly, minimizing risks associated with incorrect installations.

Illustrations accompanying the colour code aid in clarification, displaying each cable type alongside its corresponding colour. This visual guide serves as an essential reference tool for contractors and engineers who frequently work with TMT products. By utilizing these illustrations, stakeholders can ensure compliance with the colour code system, fostering a safer and more efficient working environment.

Overall, TMT Global Technology Ltd’s colour coding for net cables not only streamlines processes but also demonstrates the company’s commitment to meeting the needs of the Saudi Arabian market. The clarity and functionality of this system underscore its importance in contemporary electrical installations.

How to Read the Colour Code

Understanding the colour code used in TMT Global Technology Ltd’s net cables is crucial for efficient installation and maintenance in the Saudi Arabia market. The colours correspond to specific functions within the cable, allowing technicians and installers to quickly identify connections and ensure proper wiring. The colour code typically follows an industry-standard pattern, designed for consistency and ease of use. Below is a step-by-step guide on how to read and interpret these colour codes.

Firstly, it is essential to familiarize yourself with the cable’s exterior, as it often displays a printed legend or a drawing indicating the corresponding colours. Most TMT net cables will feature layers of insulation, each with distinct colour markings that denote different protocols or transmission standards. The basic principle is that each colour serves a specific role. For instance, common colours might include red for positive connections, black for negative, and green for data transmission paths.

Next, when opening the cable sheath, note the order of the colour-coded wires. Arrange the wires as per the specifications detailed in TMT’s technical documentation. It often includes tables or diagrams to guide the installer through the specific functions of each colour. In practical scenarios, using a multimeter can help verify connectivity and ensure that the installation conforms to the required standards.

Visual aids such as charts or diagrams can enhance comprehension. Installing professionals should refer to these tools frequently, especially during complex installations or troubleshooting processes. This systematic approach not only helps in ensuring that the wiring complies with local regulations but also maintains the integrity and performance of the net cables.

By following these steps and referring to TMT Global Technology Ltd’s resources, technicians can confidently read the colour code and make informed decisions during installation and maintenance.

Comparison with International Standards

Understanding the net cable colour code established by TMT Global Technology Ltd for the Saudi Arabia market necessitates a comparative analysis with international standards. Notably, the Telecommunications Industry Association (TIA) and the International Organization for Standardization (ISO) play significant roles in setting guidelines for colour coding in cabling systems worldwide. These standards are essential as they ensure consistency, reduce the risk of errors during installation, and facilitate maintenance across various regions.

The TIA standards, specifically TIA-568, outline a colour code scheme predominantly used in North America. This scheme identifies the arrangement of pairs within twisted-pair cables, with a systematic colour-coding method that aids in identifying wire pairs for both telecommunications and data systems. Conversely, ISO/IEC 11801, which is recognized globally, provides another robust guideline for fibre optic and copper cabling systems. While both TIA and ISO standards emphasize the importance of clear and consistent colour coding, the specific colour combinations and their meanings can differ, which is essential to consider when examining TMT’s practices.

TMT’s colour code for net cables in the Saudi market generally aligns with these established international guidelines. However, there are notable distinctions that reflect regional practices and preferences. For example, TMT may employ specific shades or additional markings to cater to local requirements or to provide improved identification under certain conditions. Such adaptations highlight the importance of regional compliance while still respecting the overarching goals of international standardization.

By comparing TMT’s colour code with TIA and ISO standards, stakeholders can better comprehend the alignment and differences that exist. Understanding these connections not only aids in compliance but also promotes safe and effective cabling practices. This thorough approach ensures that technicians and engineers operating in Saudi Arabia can effectively navigate the localised cable colour coding system while remaining aware of global best practices.

Installation Recommendations Using TMT’s Colour Code

When undertaking installations using TMT Global Technology Ltd’s net cable colour codes in the Saudi Arabian market, it is essential to adhere to recommended practices that ensure functionality, safety, and compliance with established standards. A crucial aspect of this is understanding and correctly applying the TMT colour codes throughout the entire wiring process.

To begin, it is advisable to familiarize yourself with the specific colour codes used by TMT, as these facilitate identification and differentiation of wires, reducing the risk of errors during installation. Proper documentation should be maintained throughout the process; this includes having a copy of TMT’s colour coding guide readily available for reference. Utilizing this guide will help installation teams to remain consistent, thereby avoiding confusion that might arise from incorrect wiring.

Optimal installation techniques should involve careful planning and organization of cabling routes before installation starts. This includes mapping out where each cable runs, considering both accessibility for future maintenance and aesthetics. It is recommended to use cable management systems such as racks or trays to keep the installation tidy. Additionally, while working with cables, ensure that they are not overly kinked or twisted, as this can lead to signal degradation or physical damage over time.

Common pitfalls to avoid include overlooking the importance of grounding and bonding practices. These practices play a critical role in preventing electrical interference and maintaining overall system integrity. Furthermore, ensuring that all connections are secure and properly terminated will mitigate potential issues related to intermittent signals or complete failures.

In conclusion, adhering to TMT’s colour codes and implementing these installation recommendations will contribute to a well-organized and reliable cabling infrastructure, essential for the successful deployment of technology solutions in Saudi Arabia.

Common Issues and Troubleshooting Tips

When working with net cables, particularly in the context of TMT Global Technology Ltd’s colour coding system for the Saudi Arabia market, various issues can arise if proper adherence is overlooked. A prominent problem is the potential for connectivity failures. Incorrectly wired cables can lead to intermittent connections or complete network outages, severely impacting communication and productivity. For instance, if the blue and orange pairs are reversed, the system may fail to recognize the device at the other end, resulting in a frustrating troubleshooting process.

Another common issue associated with improper colour coding is increased latency and data transmission errors. When pairs are not maintained according to TMT’s specific standards, signal degradation may occur, leading to delays and loss of data integrity. A scenario may include a company experiencing slow internet speeds during heavy usage times. Investigating the cabling may unveil that the pairs used do not match the prescribed colours, prompting a complete rewiring to restore functionality.

To avoid these complications, it’s paramount to implement some troubleshooting techniques. First, always document the wiring process. This practice not only assists in identifying potential issues early on but also creates a reference for future maintenance. Use a cable tester to ensure that each run adheres to the TMT colour code specifications. This equipment can instantly reveal misconfigurations that might otherwise go unnoticed until significant problems arise.

If issues persist, consider examining the physical condition of the cables. Damage from improper handling, exposure to environmental elements, or stress can contribute to system failures. By maintaining awareness of these pitfalls and utilizing the aforementioned troubleshooting tips, one can bolster networking reliability and uphold the superior standards outlined by TMT Global Technology Ltd.

Conclusion and Future Trends in Cable Manufacturing

In summarizing the key aspects of TMT Global Technology Ltd’s net cable colour code specifically designed for the Saudi Arabian market, it is vital to highlight the importance of clear and standardized colour coding in enhancing safety and efficiency in electrical systems. TMT’s commitment to providing a comprehensive and user-friendly colour code fosters better understanding among technicians and users, ensuring the proper handling and installation of cables. This structured approach contributes significantly to minimizing errors that could lead to safety hazards or operational inefficiencies.

Looking forward, the future of cable manufacturing appears promising, driven by the rapid pace of technological advancements. Innovations such as the integration of smart technologies into cable systems are gaining momentum, potentially transforming traditional electrical infrastructures. By incorporating sensors and communication features, these advanced cables can monitor performance metrics in real-time, thus enhancing reliability and safety.

Moreover, sustainability trends are shaping cable manufacturing practices, emphasizing the need for eco-friendly materials and production methods. Manufacturers are increasingly focusing on reducing their carbon footprints by utilizing recyclable materials and implementing energy-efficient processes. This shift not only benefits the environment but also resonates with consumers who are more informed and concerned about sustainability issues.

As cable systems become more complex, there is a likelihood of evolving colour coding practices to accommodate new functionalities and applications. TMT Global Technology Ltd may continue to innovate its colour coding systems, integrating new standards that reflect industry changes while prioritizing user comprehension. This adaptability will be crucial for the company to maintain its competitiveness in the global market and support the growing demand for reliable electrical solutions.